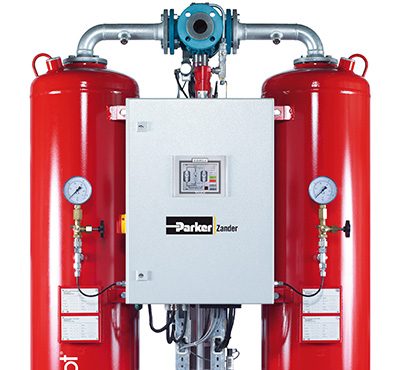

Desiccant dryers or absorption dryers are used to remove water vapour from your compressed air system. Unlike refrigerant air dryers that will reduce the pressure dew point to around +3 ºC, absorption dryers can typically reduce your dew point to -40 ºC and as low as -70 ºC. This means for water vapour to condense into a liquid, the air temperature would have to drop below -40 ºC or -70 ºC respectively. An added benefit to desiccant dry air is that a pressure dewpoint of less than -27 ºC will also prevent the growth of bacteria within the compressed air system.

Selecting the right dryer

When designing a compressed air system, not only is it important to size your air compressor correctly but also your desiccant air dryer. A common mistake is to only look at the flow capacity that a dryer is advertised at. However, pressure and temperature play a vital role when selecting a desiccant air dryer. Most dryer manufacturers advertise their flow rate at 7 bar with an ambient of 25 ºC and a compressed air temperature of 35 ºC. If any of these variables change, then the size of the dryer will be affected. It is important to understand the conditions that your new dryer will operate in, to allow for the correct size to be selected.

Desiccant air dryers come in a variety of sizes and designs. It is important to understand the difference in the various types available, as each dryer type has its advantages and disadvantages. Here at UAP we specialise in the design of compressed air systems and can help you select the best dryer to fit your system and provide the best ROI (Return on investment).